Converting lines

Coating lines for self.adhesive tape and labels

Custom tailored lines for the coating of paper and film using solvent-based, water-based or hot melt technologies.

We can provide our customers with the best available technology (BAT solutions) to be highly competitive on the market.

Photo gallery

Process description

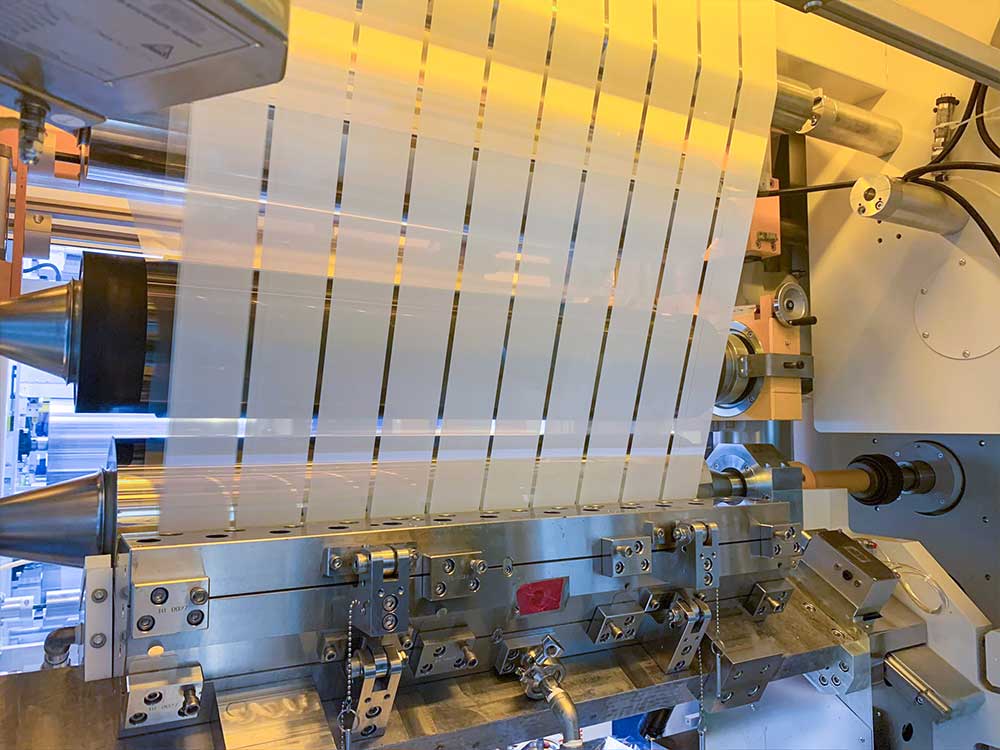

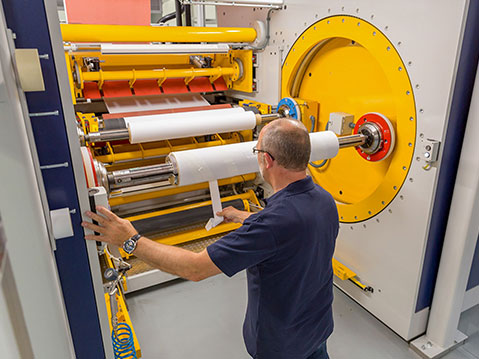

The backing unwounded by the unwinder is subsequently coated using a coating unit which can vary depending on the rheology of the adhesive to be used.

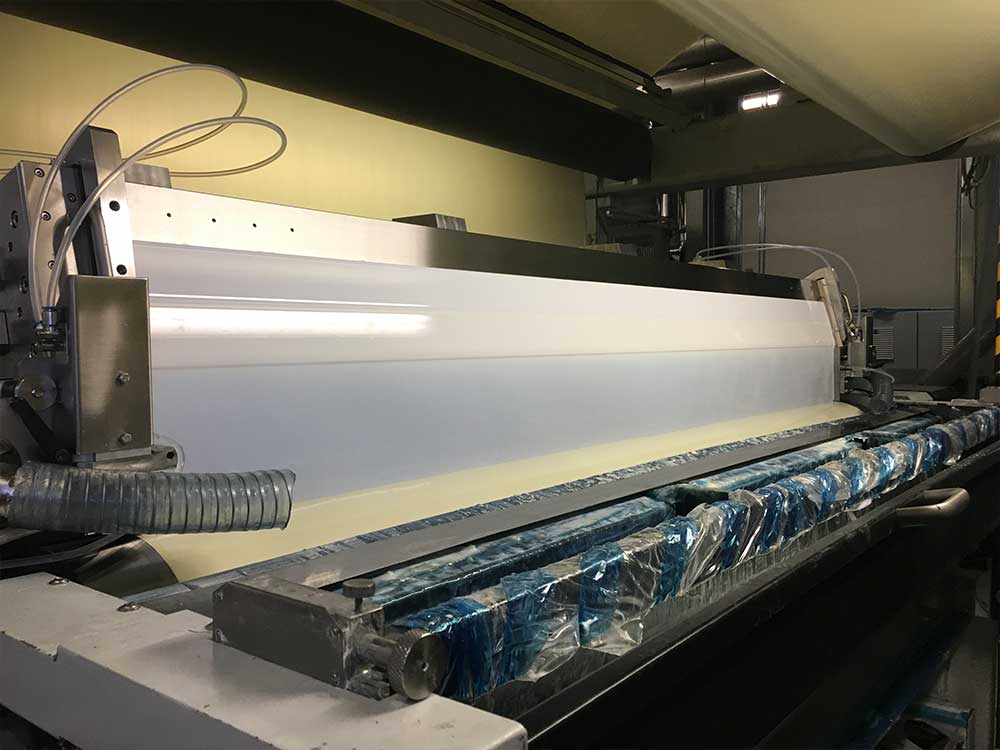

Subsequently, the coated backing enters the drying tunnel (adhesives with solvent or water vehicle) or undergoes surface cooling (hot melt adhesives) which “fixes” the coating on the support.

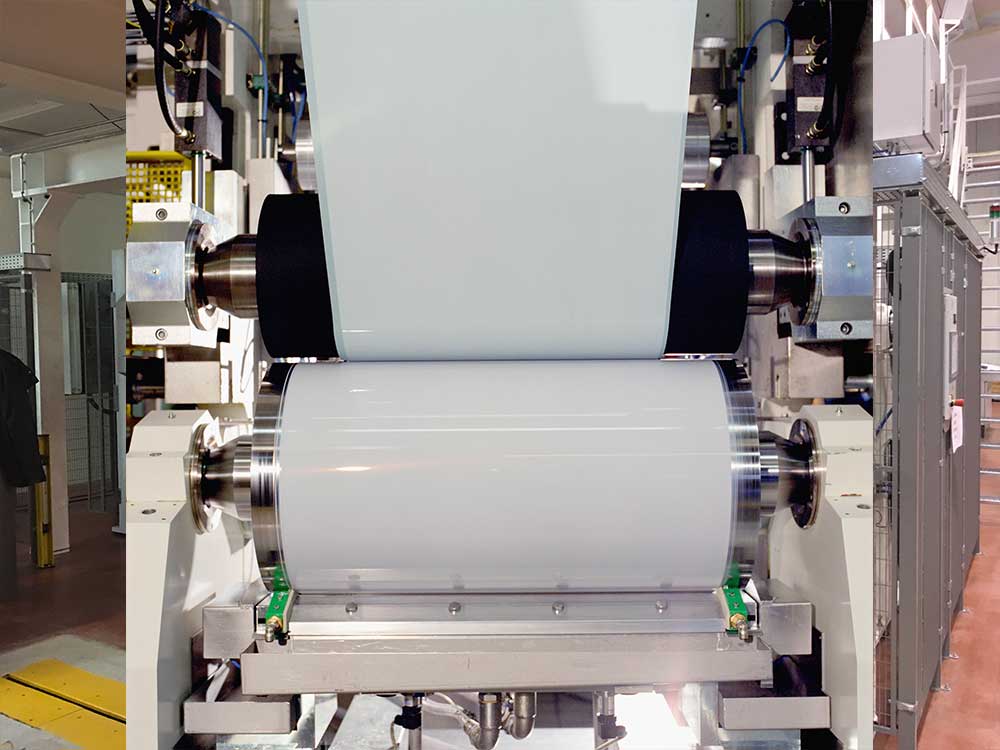

Finally, the backing can possibly be laminated and rewound onto a reel.

Depending on the process, further surface treatments of the backings may also be necessary (top coat, release coating, primer, remoisturizing, etc.).

Some special applications require UV or electron beam cross-linking.

The product obtained combines the physical/chemical properties of the various layers that compose it.

Application Sectors

Some application sectors:

- single-sided tapes

- double-sided tapes

- transfer tapes

- self-adhesive labels